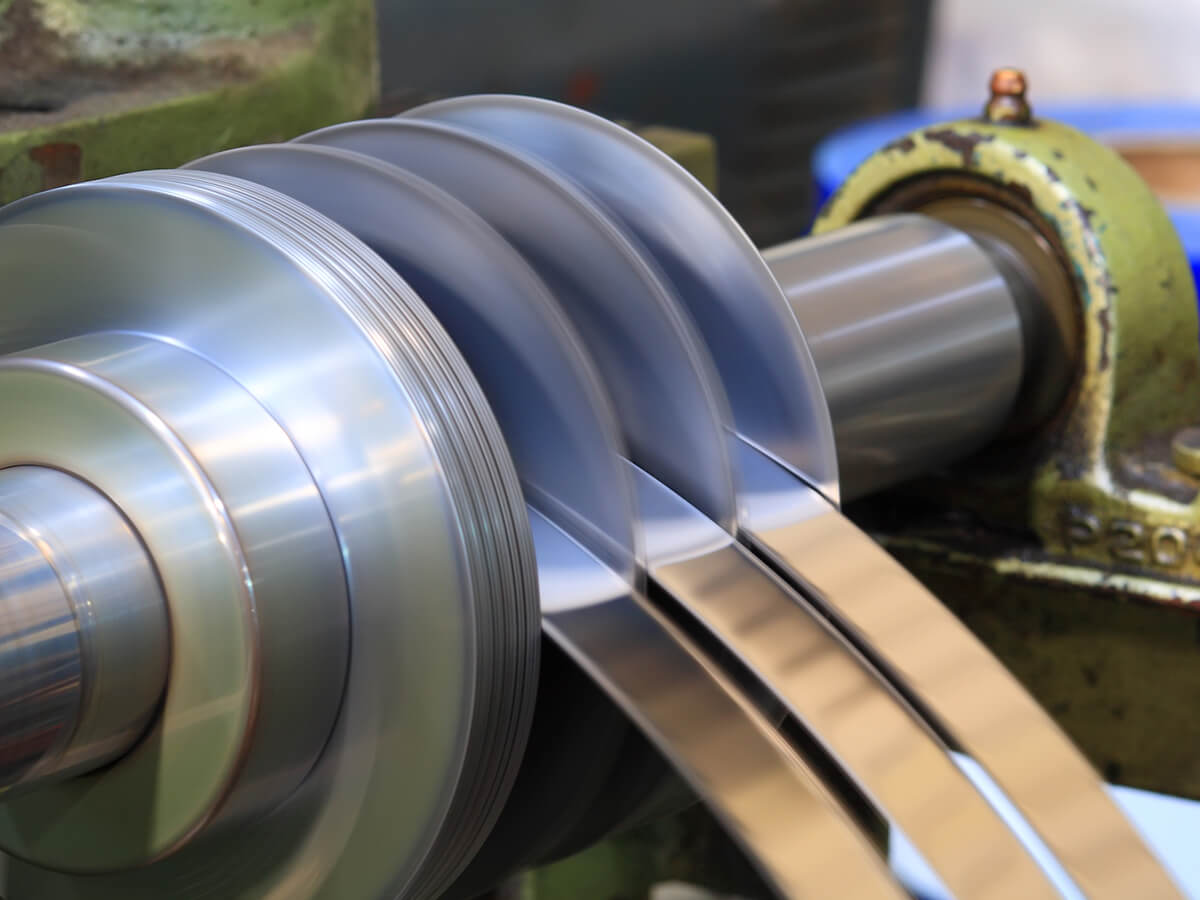

SAE 1050 COLD ROLLED STEEL STRIP CHINA SUPPLIER

Description

GRADE AISI 1050/SAE 1050 is a high-carbon, cold rolled steel containing approximately 0.50% carbon that can be hardened by heat treatment to a maximum hardness of approximately Rockwell C 58. Soft annealed high carbon steel is intended for applications requiring moderate forming, while soft spheroidized annealed product is intended for applications requiring maximum cold forming. The soft spheroidized annealed product is processed to give the lowest hardness for maximum formability. This grade of steel is used for the manufacture of blades, brackets, brake discs, clips, clutches, springs, washers and gears and for a wide range of applications that can make use of its good combination of mechanical properties.

Chemical Composition

Chemical Composition (wt%) limits of AISI 1050*

| Element | AISI 1050 |

| Carbon | 0.48-0.55 |

| Manganese | 0.60-0.90 |

| Phosphorus | 0.030 |

| Sulfur | 0.035 |

* Maximum, unless range is indicated

Hardness Requirements

Hardness requirements for ASTM A684 annealed high carbon steel (0.55% C)

| Temper | Thickness(inch) | Rockwell HardnessMin.Max. | |

| Under | Through | ||

| Soft Annealed | 0.020 0.030 0.300 | - 0.020 0.030 | 15T89.5 30T76.0 B88 |

| Soft Spheroidized Annealed | 0.020 0.030 0.300 | - 0.020 0.030 | 15T88.5 30T74.0 B85 |

Physical Properties

Physical properties for AISI 1050 steel

| Property | AISI 1050 Data |

| Density, lb/in3 | 0.284 |

| Modulus of Elasticity, psi | 29 x 106 |

| Coefficient of Thermal Expansion, 68-212˚F, /˚F | 6.39 x 10-6 |

| Thermal Conductivity, Btu/ft hr ˚F | 30.0 |

| Specific Heat, Btu/lb ˚F | 0.116 |

| Electrical Resistivity, Microohm-in | 6.42 |

Standards

Typical standards for AISI 1050 steel

| AISI 1050 |

| ASTM A684 |

Data are typical, are provided for informational purposes, and should not be construed as maximum or minimum values for specification or for final design, or for a particular use or application. The data may be revised anytime without notice. We make no representation or warranty as to its accuracy and assume no duty to update. Actual data on any particular product or material may vary from those shown herein.